Where technology meets style and functionality

Techniques and machinings

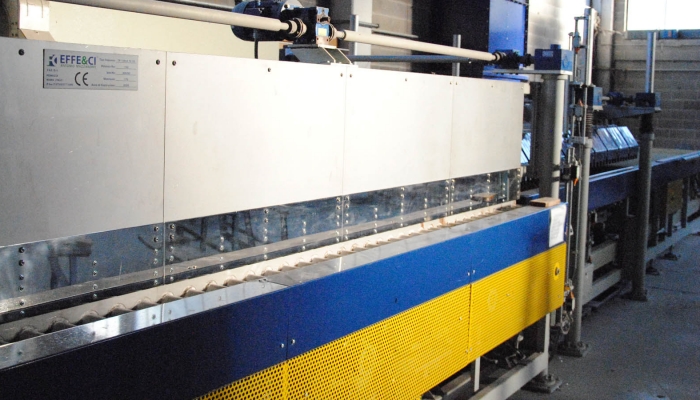

The tempered glass is accomplished through a thermal shock at about 700 °, this process makes the glass six times more resistant. The security given by tempering consists not only in increased resistance but also in the fact that, in the event of accidental breakage, the glass shatters into micro-fragments: This feature reduces the danger of injury of the persons involved.

The sandblasting process is performed by shotting sand at high pressure, useful to make the glass opaque and used as an alternative to frosted glass. It is the ideal solution for decorating your glass with lettering and logos.

The grinding is carried out to eliminate the sharp edge of the glass. With grinding polished edge is bringing out the luster and quality of the glass, being able to be shaped into a shape. Solution used on almost all types of work.

With shaping you can give the desired shape at their table, top shelves for sinks.

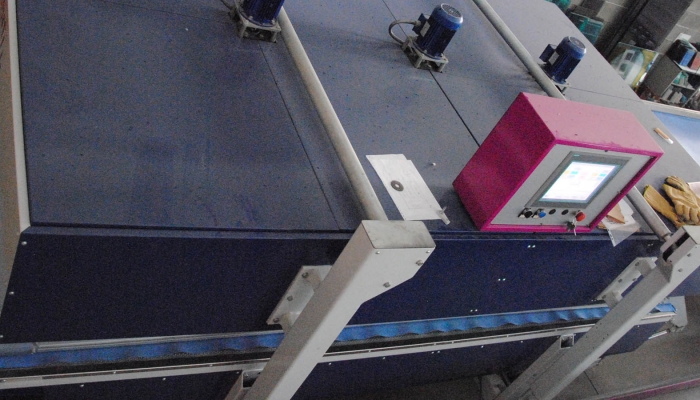

With the technique of layering assemble two or more layers of glass with the PVB plastic. This processing is performed for security requirements for makes the glass conforms to regulations.

It is used to create laminated glass, armored, bulletproof, burglary and foot traffic.

The layering make you satisfy security requirements and aesthetical goals for example using colored plastics to customize the color of your glass.

Products

- glass doors

- shower cabin

- shelves

- tables

- floorings

- parapets

- insulated glazing

- mirros

- boards

- furniture topping

- greenhouses

- verandas

First of all

customer satisfaction

Our goal is maximum customer satisfaction, to see well finished their home or business. To achieve the highest quality we rely on suppliers of systems for glass that offer the best solutions.